Revving up Your Ride: How F1 Technology Has Enhanced Everyday Cars

Published Date: 19th Mar 2023

Formula 1 racing has been at the forefront of technological innovation for decades, constantly pushing the boundaries of what's possible on the track. But many people don't realize that the technology developed for Formula 1 cars can also significantly impact everyday road cars. From improving fuel efficiency and safety to enhancing performance and handling, Formula 1 technology advancements are critical in shaping the future of the automotive industry. In this article, we'll explore some of the key ways in which Formula 1 technology is influencing the cars we drive every day and why it's so important to keep pushing the limits of what's possible on the race track.

Let's take a look at some of the technological developments that have made the jump from F1 to road cars:

Active Suspension: From F1 Innovation to Road Car Standard

In 1992, Nigel Mansell drove the Williams FW14B to victory in the Formula One World Championship, marking the beginning of a new era in motorsports technology. While the car was certainly fast, the implementation of active suspension set it apart from the competition. Active suspension technology was a game-changer for Formula One, and it has since made its way into many modern road cars.

In 1992, Nigel Mansell drove the Williams FW14B to victory in the Formula One World Championship, marking the beginning of a new era in motorsports technology. While the car was certainly fast, the implementation of active suspension set it apart from the competition. Active suspension technology was a game-changer for Formula One, and it has since made its way into many modern road cars.

What is Active Suspension?

Active suspension is a technology that allows a vehicle to adjust the level of its chassis depending on the road conditions. It works by using hydraulic or electronic systems to change the pressure in the car's suspension, which can improve the car's traction and handling. By constantly adjusting the suspension based on the car's speed, position, and other factors, the active suspension offers a smoother ride, better cornering performance, and improved stability.

How Was Active Suspension Developed in F1?

While several other companies had experimented with active suspension technology before, it was Williams that really took the idea to the next level. The team developed a hydraulic active suspension system with sensors to adjust the car's suspension constantly. The system was incredibly complex, with over 50 sensors and 100 different settings, but it allowed the team to extract the most performance possible from their cars.

During the 1992 season, the Williams team dominated the competition, winning 10 out of 16 races and securing the World Championship for Mansell. The active suspension system played a significant role in this success, allowing the drivers to maintain higher speeds and cornering performance than their competitors.

Moving from F1 to Road Cars

After its success in Formula One, active suspension technology quickly entered other motorsports areas. It was used in everything from rally cars to touring cars, and many manufacturers also began experimenting with the technology in their road cars.

One of the first road cars to feature active suspension was the 1997 Mercedes-Benz CL-Class. The system was later used in Mercedes models and vehicles from manufacturers like Audi, BMW, and Porsche. Today, the active suspension is a common feature in many high-end road cars, and it's even starting to make its way into more affordable models.

CHECK OUT OUR LATEST NEW CAR DEALS HERE

Benefits of Active Suspension

The benefits of active suspension technology are clear. By constantly adjusting the car's suspension, active suspension can improve handling, cornering performance, and stability. It can also provide a smoother ride, which is especially important for luxury vehicles.

In addition to these benefits, active suspension can also improve fuel efficiency. By reducing the amount of energy lost due to bumpy roads and uneven terrain, active suspension can help to reduce fuel consumption and emissions. This is why many modern hybrid and electric vehicles are now equipped with active suspension systems.

Conclusion

Active suspension is an excellent example of technology that was first pioneered on the circuit before making its way into mainstream vehicles. While it was initially developed for Formula One, it has since become a common feature in many road cars, and it's easy to see why. Active suspension can provide a better driving experience for anyone behind the wheel by improving handling, cornering performance, and stability. And with the continued development of electric and hybrid vehicles, it's likely that active suspension will continue to play an important role in the automotive industry for years to come.

How F1 Steering Wheel Buttons Changed the Way We Drive

In modern cars, steering wheel buttons are an essential feature that allows drivers to control various functions without taking their hands off the wheel. From adjusting the radio volume to answering a phone call, these buttons make driving easier and safer. But did you know that the origins of these buttons can be traced back to Formula One racing?

In modern cars, steering wheel buttons are an essential feature that allows drivers to control various functions without taking their hands off the wheel. From adjusting the radio volume to answering a phone call, these buttons make driving easier and safer. But did you know that the origins of these buttons can be traced back to Formula One racing?

In the 1970s, F1 teams started experimenting with buttons on their steering wheels. As more and more technology was introduced in F1 cars in the 80s and 90s, the use of buttons on the steering wheel became increasingly common. The reason was simple: it's difficult for drivers to look for buttons or dials while travelling at high speeds, so it made sense to put them on the steering wheel to access them easily.

Over time, the number of buttons on F1 steering wheels has increased significantly. Modern F1 steering wheels feature more than 20 buttons and switches, each with a specific function. For example, there are buttons to adjust the engine mode, control the differential, activate the DRS, and much more.

The Evolution of Steering Wheel Buttons

While F1 teams were the first to adopt steering wheel buttons, the technology quickly entered other motorsport areas. It wasn't long before buttons started appearing on the steering wheels of touring, rally, and other racing vehicles.

Eventually, as the technology became more widespread and affordable, it started appearing in mainstream road cars. Today, almost every car comes with steering wheel buttons, which can be used to control everything from the stereo system to the headlights.

Benefits of Steering Wheel Buttons

The benefits of steering wheel buttons are clear. Allowing drivers to control various functions without taking their hands off the wheel makes driving safer and more convenient. This is especially important when it comes to features like answering phone calls or adjusting the radio, which can be distracting if done manually.

In addition to making driving safer and more convenient, steering wheel buttons also allow for more advanced features to be included in cars. For example, many modern cars feature voice-activated assistants that can be controlled using buttons on the steering wheel. This type of technology would be difficult to implement without the use of steering wheel buttons.

CHECK OUT OUR LATEST NEW CAR DEALS HERE

Conclusion

Steering wheel buttons are a great example of how technology developed for Formula One racing can influence the cars we drive every day. What started as a way to make driving easier for F1 drivers has become a standard feature in almost every car on the road. And as technology continues to evolve, it's likely that steering wheel buttons will continue to play an important role in the way we interact with our cars.

Introduction of Hybrid Powertrains

Introducing hybrid powertrains into Formula 1 was a major turning point in the sport's history. Not only did it represent a significant technological advancement, but it also marked the beginning of a new era of more environmentally conscious racing. In this article, we will explore the origins of hybrid powertrains in F1 and how they have developed over time to become a common feature in mainstream vehicles.

Introducing hybrid powertrains into Formula 1 was a major turning point in the sport's history. Not only did it represent a significant technological advancement, but it also marked the beginning of a new era of more environmentally conscious racing. In this article, we will explore the origins of hybrid powertrains in F1 and how they have developed over time to become a common feature in mainstream vehicles.

The use of hybrid technology in motorsport can be traced back to the early 2000s when the first hybrid concept cars were introduced. However, it wasn't until the 2009 season that F1 teams were permitted to use kinetic energy recovery systems (KERS) in their cars. KERS allowed drivers to recover energy that would otherwise be lost during braking and store it in a battery for later use. This energy could then be used to provide an additional power boost during acceleration, helping to improve the car's performance.

The introduction of KERS was seen as a major step forward in F1 technology, but it wasn't until 2014 that hybrid powertrains became mandatory. This was part of a broader push by F1 to become more environmentally conscious and reduce its carbon footprint. The new hybrid powertrains allowed for even greater energy recovery, with energy being recovered from braking and the heat generated by the car's exhaust.

The new hybrid powertrains were a significant technological leap forward for F1 but were also a major challenge for teams. The new systems were more complex and required more maintenance than previous powertrains. However, teams were quick to adapt, and by the end of the 2014 season, most were able to get the most out of their hybrid systems.

Since their introduction into F1, hybrid powertrains have continued to evolve and improve. In recent years, advancements in battery technology and energy recovery systems have allowed for even greater efficiency and performance. And while F1 remains the ultimate testing ground for new technologies, hybrid powertrains have also become increasingly common in mainstream vehicles.

CHECK OUT OUR LATEST NEW CAR DEALS HERE

Hybrid cars are now becoming more popular than ever before, with many drivers attracted to their reduced fuel consumption and lower emissions. Advances have helped the popularity of hybrid vehicles in battery technology, which has made hybrid cars more practical and affordable for everyday use. Today, a wide variety of hybrid vehicles are available, from small city cars to large SUVs.

In conclusion, introducing hybrid powertrains into F1 was significant in the sport's history. It represented a major technological leap forward and a commitment to more environmentally conscious racing. Since their introduction, hybrid powertrains have continued to evolve and improve, and they have become increasingly common in mainstream vehicles. As drivers continue to prioritize fuel efficiency and lower emissions, it is likely that hybrid technology will continue to play an increasingly important role in the future of the automotive industry.

Using Carbon Fiber in Road Cars

Carbon fiber is a material that has revolutionized the automotive industry. Lightweight, strong, and durable, it has become popular for high-performance vehicles, particularly in motorsports. Its origins in Formula 1 (F1) racing, where it was first introduced as a way to improve car performance, and its gradual transition into everyday cars is an interesting story.

Carbon fiber is a material that has revolutionized the automotive industry. Lightweight, strong, and durable, it has become popular for high-performance vehicles, particularly in motorsports. Its origins in Formula 1 (F1) racing, where it was first introduced as a way to improve car performance, and its gradual transition into everyday cars is an interesting story.

The first use of carbon fiber in F1 can be traced back to the 1981 season when McLaren introduced a car made entirely of carbon fiber. The car, called the MP4/1, was a game-changer, providing significant weight savings and improved stiffness over traditional metal construction. The use of carbon fiber allowed McLaren to gain a significant advantage over their competitors, and it wasn't long before other teams followed suit.

Despite its initial success, the use of carbon fiber in F1 was not without its challenges. The material was expensive, difficult to work with, and required specialist knowledge to manufacture. But the benefits of using carbon fiber in F1 were clear. It allowed for greater design flexibility, improved aerodynamics, and, most importantly, better performance.

As the years went by, the use of carbon fiber in F1 became more widespread. Today, every F1 team uses carbon fiber extensively in their cars, with the chassis, bodywork, and some of the internal components made from the material. The use of carbon fiber has become so widespread in F1 that it is now seen as an essential part of car design and development.

The success of carbon fiber in F1 racing soon caught the attention of the automotive industry. As the technology became more advanced and the manufacturing processes more efficient, the cost of producing carbon fiber components started to come down. This allowed manufacturers to start using carbon fiber in their high-end sports cars and eventually in more mainstream vehicles.

One of the first cars to use carbon fibre extensively was the iconic McLaren F1, introduced in 1992. The car featured a carbon fiber monocoque chassis, which provided significant weight savings and improved safety in the event of a crash. Using carbon fiber in the McLaren F1 helped pave the way for other high-end sports cars to follow suit.

Today, carbon fiber is used extensively in the automotive industry, with many manufacturers using it for everything from bodywork and chassis components to suspension and interior trim. While the material is still expensive compared to traditional metal construction, advancements in manufacturing techniques have made it more accessible to manufacturers.

In conclusion, the introduction of carbon fiber into F1 racing has had a significant impact on the automotive industry. What was once an expensive and specialist material used only in the highest levels of motorsports is now a popular choice for high-end sports cars and even some mainstream vehicles. As technology continues to evolve, it is likely that we will see even more widespread use of carbon fiber in the cars of the future.

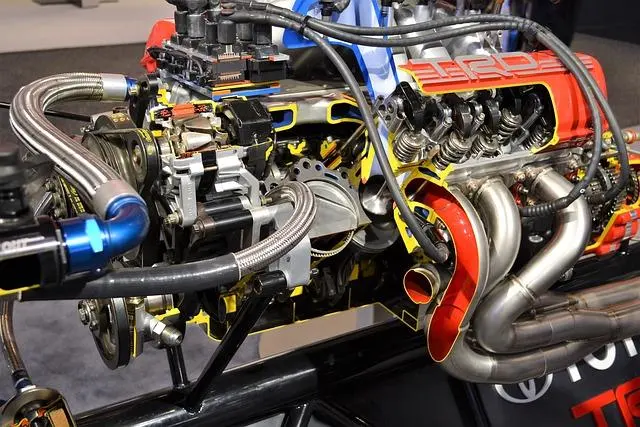

Introduction of Turbo Chargers

Turbochargers are essential to modern car design, improving performance and fuel efficiency. But did you know that the first turbocharged engines were actually developed in Formula 1 (F1) racing? In this article, we will explore the history of turbochargers in F1 and how they made the transition into mainstream cars.

Turbochargers are essential to modern car design, improving performance and fuel efficiency. But did you know that the first turbocharged engines were actually developed in Formula 1 (F1) racing? In this article, we will explore the history of turbochargers in F1 and how they made the transition into mainstream cars.

The French manufacturer Renault developed the first turbocharged engine to be used in F1 racing in the late 1970s. At the time, turbochargers were a relatively new concept in motorsport, and many people were sceptical about their potential benefits. However, Renault persisted with their turbocharged engine, and in 1979, they became the first team to win an F1 race with a turbocharged car.

The introduction of turbochargers in F1 racing marked a significant milestone in automotive history. The technology allowed for smaller engines to produce more power, providing a significant advantage over traditional naturally aspirated engines. As other teams started to adopt turbocharged engines, the technology began to evolve rapidly, with manufacturers constantly seeking new ways to improve performance and reliability.

However, the use of turbochargers in F1 racing was not without its challenges. The technology was still in its infancy, and the engines were notoriously difficult to manage. Turbocharged engines required a lot of maintenance and were prone to overheating, which could cause significant damage.

Despite these challenges, the benefits of turbochargers in F1 racing were clear, and the technology continued to evolve. By the 1980s, turbocharged engines produced more than 1,000 horsepower, providing incredible performance levels.

As turbocharged engines became more widespread in F1 racing, the technology began to make its way into mainstream cars. In the early 1980s, manufacturers such as Porsche and BMW started to produce turbocharged engines for their sports cars, significantly boosting performance.

CHECK OUT OUR LATEST NEW CAR DEALS HERE

However, it wasn't until the 1990s that turbochargers became more widespread in mainstream cars. Advances in manufacturing techniques and improvements in engine management systems made it possible for manufacturers to produce turbocharged engines that were more reliable and efficient.

Today, turbocharged engines are used extensively in the automotive industry, with many manufacturers using them to improve performance and fuel efficiency. Turbochargers are particularly popular in high-performance sports cars, providing significant acceleration and top-speed benefits.

In conclusion, the introduction of turbochargers in F1 racing marked a significant milestone in automotive history. The technology allowed for smaller engines to produce more power, providing a significant advantage over traditional naturally aspirated engines. As the technology evolved, turbochargers transitioned into mainstream cars, which are now a popular choice for improving performance and fuel efficiency.

Ceramic Brakes and Stopping Power

Ceramic brakes are high-performance braking systems that are commonly found in many modern-day sports cars. The technology was first introduced in Formula 1 racing, where it quickly became a favourite among teams due to its superior performance characteristics. In this article, we will explore the history of ceramic brakes in F1 and how they made the transition into mainstream cars.

Ceramic brakes are high-performance braking systems that are commonly found in many modern-day sports cars. The technology was first introduced in Formula 1 racing, where it quickly became a favourite among teams due to its superior performance characteristics. In this article, we will explore the history of ceramic brakes in F1 and how they made the transition into mainstream cars.

The German manufacturer, Messerschmitt-Bölkow-Blohm (MBB) developed the first ceramic brake system in the 1970s. The company developed the system for use in aircraft, where it was used to reduce weight and improve braking performance. However, it wasn't until the 1980s that ceramic brakes began to make their way into the world of motorsport.

In 1988, the Porsche 962C became the first race car to be fitted with ceramic brakes. The system was developed in collaboration with the French company SICOM and offered significant advantages over traditional metal brakes. Ceramic brakes are made from a composite material that includes carbon fibres and ceramic particles, which makes them incredibly strong and durable. They also have excellent heat dissipation properties, which means they are less likely to fade or lose performance under high temperatures.

The introduction of ceramic brakes in F1 racing marked a significant milestone in automotive history. The technology offered teams a significant advantage, providing better braking performance and reduced weight. However, the use of ceramic brakes was not without its challenges. The high cost of the technology made it prohibitive for many teams, and the brakes required a lot of maintenance and careful handling to ensure they operated effectively.

Despite these challenges, the benefits of ceramic brakes in F1 racing were clear, and the technology continued to evolve. Over time, improvements in manufacturing techniques and materials science made it possible to produce ceramic brakes that were more reliable and affordable.

CHECK OUT OUR LATEST NEW CAR DEALS HERE

Today, ceramic brakes are available in many high-end sports cars, including Porsche, Ferrari, and Lamborghini models. They are particularly popular in track-focused sports cars, where they offer significant performance benefits. Ceramic brakes provide improved stopping power, reduced weight, and less fade than traditional metal brakes, making them ideal for high-performance vehicles.

In conclusion, the introduction of ceramic brakes in F1 racing marked a significant milestone in automotive history. The technology offered teams a significant advantage, providing better braking performance and reduced weight. Over time, improvements in manufacturing techniques and materials science made it possible to produce ceramic brakes that were more reliable and affordable, leading to their adoption in mainstream sports cars. Today, ceramic brakes are a popular choice for high-performance vehicles, offering improved performance and safety on both the road and the track.

Formula 1 motorsport has been a key driver in the development of new technologies for everyday cars. F1 teams have access to vast resources and budgets, allowing them to experiment with new materials, technologies, and engineering methods that can be adapted for commercial vehicles. Many of the technologies that we take for granted in modern cars, such as carbon fiber construction, turbochargers, and ceramic brakes, were first developed in F1 racing. By pushing the boundaries of what is possible in motorsport, F1 teams have helped to drive innovation and technological advancement in the automotive industry, leading to safer, more efficient, and more sustainable vehicles for everyone.